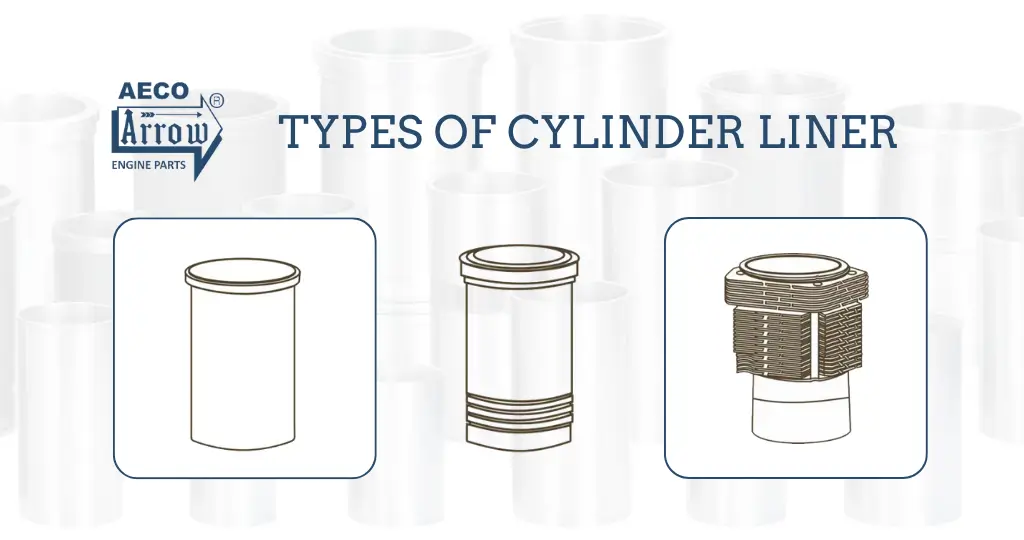

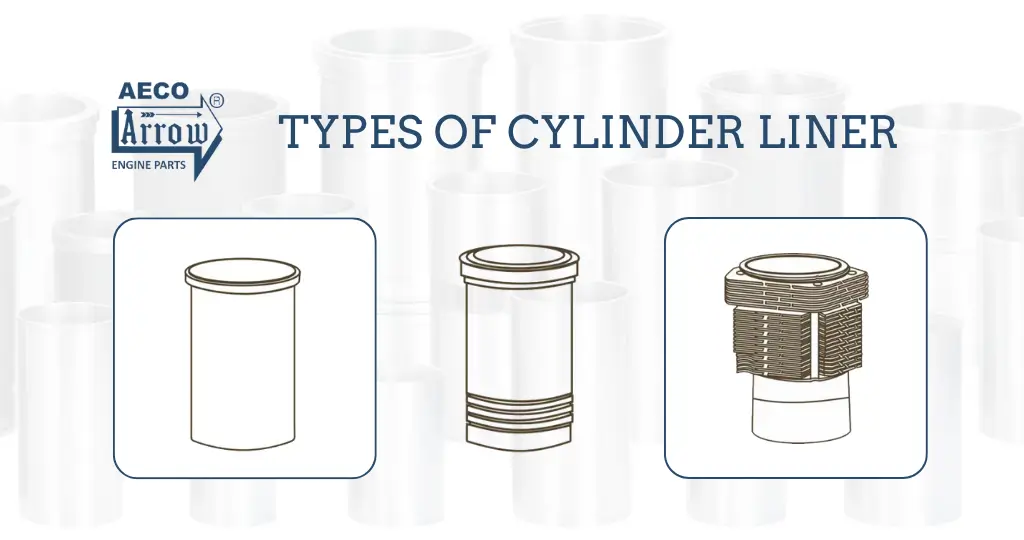

Overview: Dry cylinder liners, also known as "sleeve" liners, are characterized by their installation directly into the engine block without any contact with the engine coolant. This design allows them to operate independently of the water jacket, relying on alternative cooling methods such as air or oil.

Applications: Commonly found in high-performance and racing engines, dry cylinder liners are favoured for their efficiency in dissipating heat and reducing overall engine weight. Their design caters to applications where optimal performance is paramount.

Advantages: The primary advantage of dry cylinder liners lies in their efficient heat dissipation mechanisms. By relying on air or oil for cooling, these liners avoid the complexities associated with water-based systems. Additionally, the reduced weight contributes to improved power-to-weight ratios, a critical factor in high-performance engines.

Drawbacks: While ideal for racing and high-performance applications, dry cylinder liners may face challenges in regulating temperatures in prolonged and intense usage scenarios. The absence of direct contact with engine coolant limits their ability to handle extreme thermal loads.

Heat Dissipation: Depend on air or oil for heat dissipation, offering efficient cooling in high-performance scenarios.

Ideal for high-performance and racing engines where weight and heat dissipation are critical.

Weight and Complexity: Tend to be lighter due to the absence of a water jacket, contributing to improved power-to-weight ratios.

Overview: Wet cylinder liners, in contrast, are designed to be in direct contact with the engine coolant. These liners are surrounded by a water jacket, facilitating the transfer of heat from the liner to the coolant for effective cooling.

Applications: Wet cylinder liners find widespread use in automotive and industrial engines where consistent and efficient cooling is paramount. This design is well-suited for applications with high thermal loads, ensuring the engine operates within optimal temperature ranges.

Advantages: The key advantage of wet cylinder liners lies in their superior cooling capabilities. By integrating a water jacket, these liners effectively regulate engine temperatures, preventing overheating and enhancing overall engine efficiency. This design also allows for greater flexibility in adapting to various operating conditions. Drawbacks: The inclusion of a water jacket adds weight and complexity to the engine system. Additionally, the reliance on coolant makes wet cylinder liners more susceptible to issues such as corrosion and cooling system maintenance requirements.

Heat Dissipation: Utilizez engine coolant for effective heat transfer, ensuring consistent cooling in various operating conditions.

Widely used in automotive and industrial engines, providing consistent cooling in diverse applications.

Weight and Complexity: Includes a water jacket, adding weight and complexity to the engine system.

Overview: Air-cooled cylinder liners represent a distinct design philosophy where heat dissipation is achieved through the flow of air over the engine's exterior surface. This design eliminates the need for a water jacket and associated coolant.

Applications: Commonly associated with motorcycles and certain small engines, air- cooled cylinder liners are chosen for their simplicity and efficiency. They are often preferred in applications where water cooling systems may be impractical or undesirable.

Advantages: The simplicity of air-cooled cylinder liners translates to reduced weight and lower maintenance requirements. These liners are well-suited for applications where lightweight design and ease of maintenance are critical factors.

Drawbacks: Despite their advantages, air-cooled cylinder liners may face challenges in maintaining optimal operating temperatures, especially under heavy and prolonged usage. The absence of a water jacket limits their ability to handle extreme thermal loads efficiently.

Heat Dissipation: Rely on ambient air for cooling, eliminating the need for a water-based system but may face challenges in extreme conditions.

Found in motorcycles and applications where water cooling is impractical or undesirable due to simplicity and reduced weight.