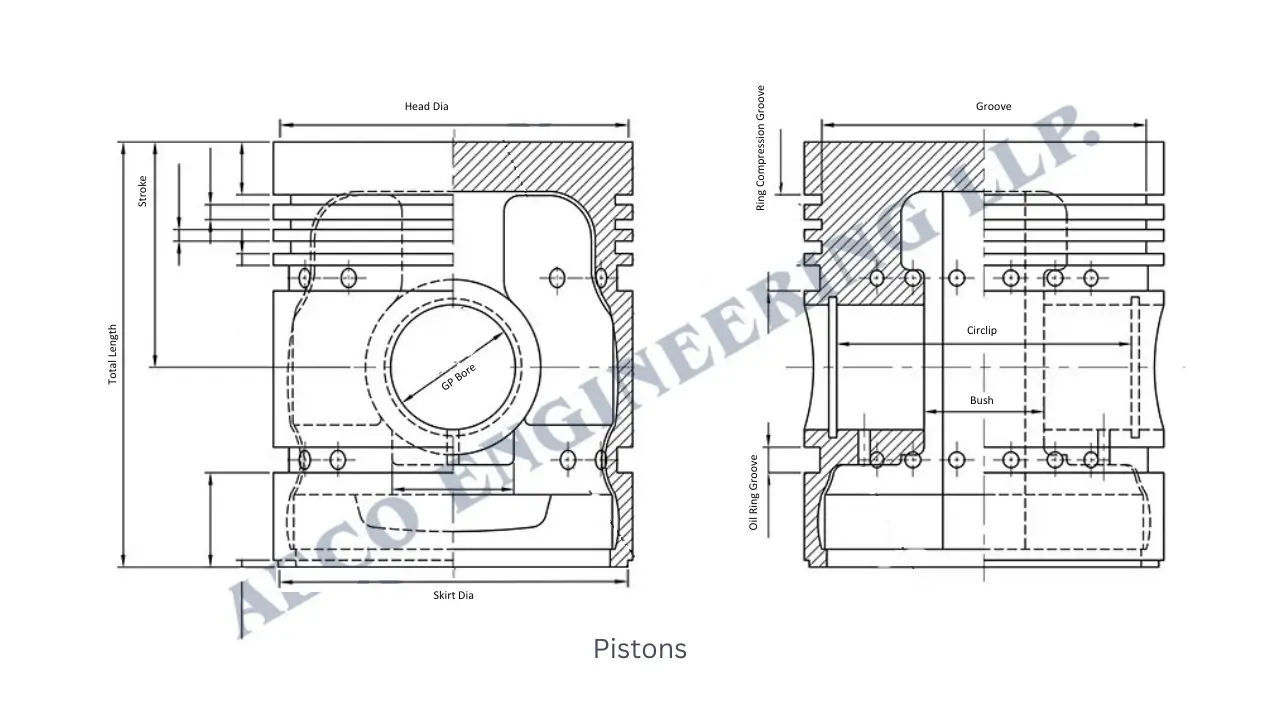

Crafted from new alloys with exceptional wear resistance at operating temperatures, our pistons excel in prolonged performance. The material's high conductivity ensures efficient cooling, while the lightweight and sturdy design promotes effectiveness over extended periods. Resistance to wear in ring grooves, skirts, and gudgeon pinholes is significantly increased. Our alloy piston castings undergo precise heat treatment and aging, ensuring dimensional strength in service. Elevate your engine's performance with our meticulously crafted pistons.

As a leading manufacturer and exporter of aftermarket pistons, we specialize in crafting these components with precision to meet the specifications and requirements of clients worldwide. Our pistons adhere strictly to international standards and serve as OEM replacements for various vehicles. With ISO 9001:2015 certification, we stand as the largest piston manufacturer in India. Trust us for top-quality aftermarket pistons that guarantee performance and reliability.

| Particulars | Specification |

|---|---|

| Hardness | ALU - 70(HRB) CI - 90(HRB) |

| Size Range (In diameter) | 50 - 200 |

| Tensile | 210 - 275 n/mm2 |

| Material | Aluminium & CI Alloy |

| Chemical Composition | |

| Copper (Cu) | Min 1 – Max 1.50 |

| Magnesium (Mg) | Min 1 – Max 1.50 |

| Silicon (Si) | Min 12 – Max 14 |

| Manganese (Mn) | Max 0.20 |

| Nickel (Ni) | Min 1 – Max 1.5 |

| Aluminium + Alloy | Rem |

| Brand | AECO, ARROW |

We produce a diverse range of pistons designed for use in contemporary internal combustion engines. Leveraging our manufacturing expertise, we specialize in crafting aluminum pistons that optimize loads through advanced material development and cutting-edge metal-matrix technologies. Our commitment to innovation ensures that our pistons deliver unparalleled performance and durability in today's engines. Explore our comprehensive lineup for superior quality and precision-engineered pistons.

ZETOR

ZETOR

America (USA) America (USA) |

Australia Australia |

Argentina Argentina |

Algeria Algeria |

Azerbaijan Azerbaijan |

Bangladesh Bangladesh |

Belarus Belarus |

Bolivia Bolivia |

Brazil Brazil |

Bulgaria Bulgaria |

Cameroon Cameroon |

Canada Canada |

Chile Chile |

Colombia Colombia |

Czech Republic Czech Republic |

Djibouti Djibouti |

Dominic Republic Dominic Republic |

Ecuador Ecuador |

Egypt Egypt |

Ethiopia Ethiopia |

Germany Germany |

Ghana Ghana |

United Kingdom (UK) United Kingdom (UK) |

Greece Greece |

Guatemala Guatemala |

Indonesia Indonesia |

Iran Iran |

Iraq Iraq |

Israel Israel |

Jordan Jordan |

Kazakhstan Kazakhstan |

Kenya Kenya |

Lebanon Lebanon |

Libya Libya |

Malaysia Malaysia |

Mauritania Mauritania |

Mexico Mexico |

Mongolia Mongolia |

Morocco Morocco |

Mozambique Mozambique |

Myanmar Myanmar |

Netherlands Netherlands |

Nigeria Nigeria |

Panama Panama |

Peru Peru |

Philippines Philippines |

Poland Poland |

Qatar Qatar |

Romania Romania |

Russia Russia |

Saudi Arabia Saudi Arabia |

Singapore Singapore |

Slovenia Slovenia |

Somalia Somalia |

South Korea South Korea |

South Africa South Africa |

Spain Spain |

Sri Lanka Sri Lanka |

Sudan Sudan |

Syria Syria |

Taiwan Taiwan |

Tanzania Tanzania |

Thailand Thailand |

Tunisia Tunisia |

United Arab Emirates (UAE) United Arab Emirates (UAE) |

Uganda Uganda |

Uruguay Uruguay |

Uzbekistan Uzbekistan |

Venezuela Venezuela |

Vietnam Vietnam |

Yemen Yemen |

Zimbabwe Zimbabwe |

Minimum order quantity for Pistons is 500 pieces and 1000 for new development.

We can offer material compositions using high nickel, high silicon or as per customer specifications meeting to respective country standards.

We manufacture Alfin, Steel Strip, Oil Cooling Gallery, Articulated and Normal Pistons

Yes, only to direct bulk Importers.

Yes, we manufacture custom pistons.

Yes, We do private labeling of Pistons.