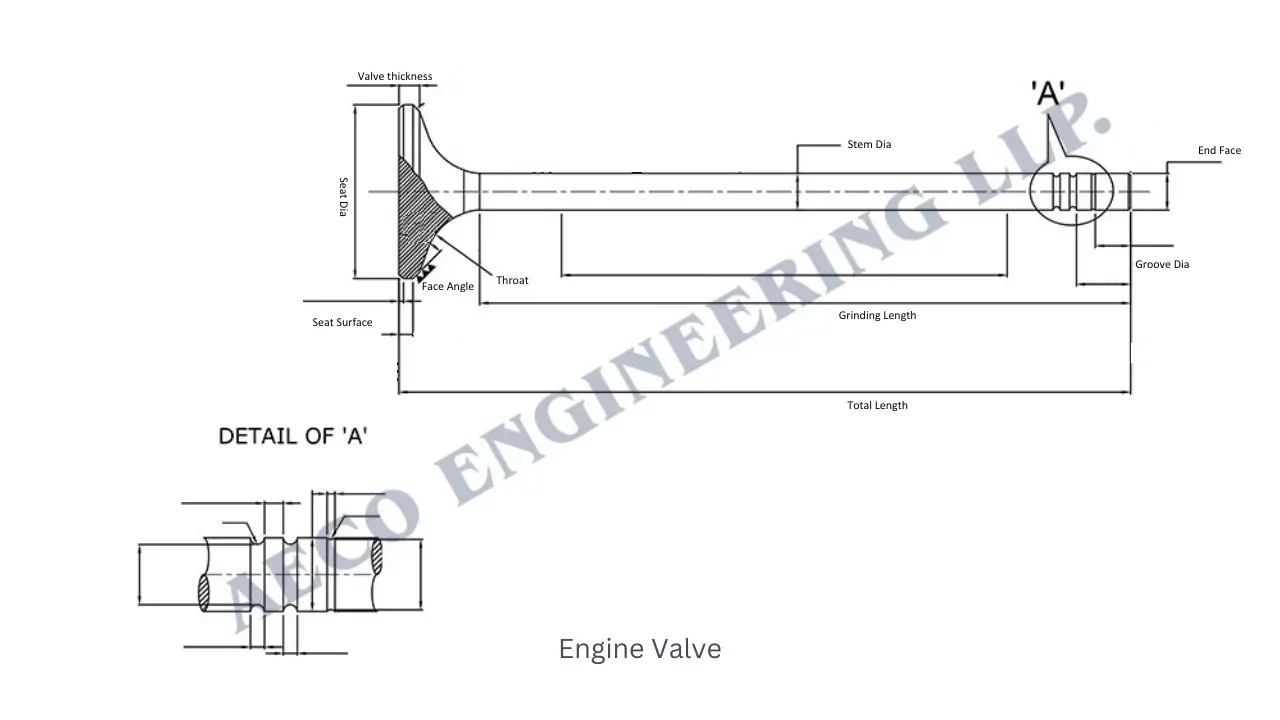

The engine valve stands as a vital and intricately crafted component within any engine. Utilizing electrically induced disturbance and precise manufacturing techniques, it is meticulously shaped to meet exacting standards. Through precision machining, the valve is expertly cut into its final, high-performing form. Our commitment to excellence ensures that each engine valve undergoes a meticulous process, resulting in top-quality, precisely crafted products that play a critical role in engine performance. Explore the precision and quality of our engineered engine valves for optimal functionality and reliability in every engine

Our inlet valves are crafted from chrome-silicon alloy steel, while exhaust valves are manufactured using chrome-nickel-silicon alloy steel, specifically engineered to excel in high-temperature and high-pressure conditions. As part of our manufacturing process, all engine valves undergo meticulous heat treatment, significantly enhancing toughness and wear resistance, particularly in stem and seating areas. Additionally, our valves undergo rigorous 100% crack detection, ensuring the highest standards of quality and reliability. Trust our precision-engineered engine valves for optimal performance and durability in demanding operating conditions.

| Particulars | Specification |

|---|---|

| Stem Diameter | 4 - 19mm |

| Head Diameter | 15.20 - 85mm |

| Length | 50 - 300mm |

| Material | Low Carbon Steel, Martensitic & Authentic grades of valve steels and Super Alloys |

| Brand | AECO, ARROW |

Our engineering information and experience in the field of internal combustion Engine Valves empower us to give customers an appropriate valve that includes the essential characteristics that are needed to perform at the anticipated efficiency, durability, and life expectancy. Whether you require modification of an existing Engine Valve or wish to design and develop a new Engine Valve with specific requirements, AECO Engineering has the knowledge, experience, and proper tools to comply with any demand. We are an ISO-certified 9001:2015 and the largest Engine Valve manufacturer in India.

ZETOR

ZETOR

America (USA) America (USA) |

Australia Australia |

Argentina Argentina |

Algeria Algeria |

Azerbaijan Azerbaijan |

Bangladesh Bangladesh |

Belarus Belarus |

Bolivia Bolivia |

Brazil Brazil |

Bulgaria Bulgaria |

Cameroon Cameroon |

Canada Canada |

Chile Chile |

Colombia Colombia |

Czech Republic Czech Republic |

Djibouti Djibouti |

Dominic Republic Dominic Republic |

Ecuador Ecuador |

Egypt Egypt |

Ethiopia Ethiopia |

Germany Germany |

Ghana Ghana |

United Kingdom (UK) United Kingdom (UK) |

Greece Greece |

Guatemala Guatemala |

Indonesia Indonesia |

Iran Iran |

Iraq Iraq |

Israel Israel |

Jordan Jordan |

Kazakhstan Kazakhstan |

Kenya Kenya |

Lebanon Lebanon |

Libya Libya |

Malaysia Malaysia |

Mauritania Mauritania |

Mexico Mexico |

Mongolia Mongolia |

Morocco Morocco |

Mozambique Mozambique |

Myanmar Myanmar |

Netherlands Netherlands |

Nigeria Nigeria |

Panama Panama |

Peru Peru |

Philippines Philippines |

Poland Poland |

Qatar Qatar |

Romania Romania |

Russia Russia |

Saudi Arabia Saudi Arabia |

Singapore Singapore |

Slovenia Slovenia |

Somalia Somalia |

South Korea South Korea |

South Africa South Africa |

Spain Spain |

Sri Lanka Sri Lanka |

Sudan Sudan |

Syria Syria |

Taiwan Taiwan |

Tanzania Tanzania |

Thailand Thailand |

Tunisia Tunisia |

United Arab Emirates (UAE) United Arab Emirates (UAE) |

Uganda Uganda |

Uruguay Uruguay |

Uzbekistan Uzbekistan |

Venezuela Venezuela |

Vietnam Vietnam |

Yemen Yemen |

Zimbabwe Zimbabwe |

Minimum order quantity for Engine Valves is 300 pieces.

We can offer material compositions using Iron, Nickel, Zink, Lead, Tin, Titanium or as per customer specifications meeting to respective country standards.

We manufacture Mono-Metal Valves, Bi-Metal Valves, Seat Stellite, Tip & Seat Induction Hardening, Chrome Plated, With Scrapper, Stainless Steels with or without Tufftriding, Hard Chrome/Nitrided Stem, Profile & Through Hardened Grooves, Shrouded and Reduced Stem

Yes, to direct bulk importers.

Yes, we manufacture custom Valves.

Yes, We do private labeling of Engine Valve.