AECO produces Cylinder Liners suitable for various applications, including tractors, cars, trucks, compressors, and generators. The company also offers customization services, assembling and manufacturing auto cylinder liners based on customer-provided details, drawings, or samples. This flexibility allows AECO to meet the specific requirements of their customers in the automotive and industrial sectors.

AECO manufactures Cylinder Liners in gray cast iron utilizing Centrifugal Casting. Even unique chemical compositions adding molybdenum are used to ensure corrosion resistance properties and upgraded lubrication. The centrifugal casting cycle is known to be the best technique for Cylinder liner manufacturers. In centrifugal casting, a permanent mold is rotated constantly about its axis at high speeds as the liquid metal is poured. The centrifugal power causes the metal to circulate itself uniformly around the die. The resulting casting is a fine-grained casting with a very fine-grained outer diameter, owing to chilling against the mold surface. Impurities and inclusions float to the surface of the inside diameter, which can be machined away.

| Particular | Specifications |

|---|---|

| Bore Diameter | 50 - 220 |

| Total Length | 110 - 470 |

| Hardness | 97 - 102(HRB) 223 - 255(BHN) |

| Tensile | 210 - 275 n/mm2 |

| Finish | Semi and Fully Finished |

| Chemical Compostion | |

| Chromium | Min 0.25 - Max 0.50 |

| Carbon | Min 3 - Max 3.50 |

| Silicon | Min 2 - Max 2.50 |

| Manganese | Min 0.50 - Max 0.80 |

| Phosphorus | Min 0.3 - Max 0.50 |

| Sulphur | Max 0.05 |

| Brand | AECO, ARROW |

AECO Engineering prioritizes product quality and maintains a rigorous quality assurance process. The company has invested in specialized equipment, including Gauges, Roughness Tester, Slip Gauges, Height Gauges, Metallurgical Microscope, Spectrometer, Hardness Tester, and Roundness Tester. These tools are utilized by their Quality Control team to ensure the highest standards. The on-site spectrometer is employed to monitor and maintain the chemical composition for each casting group, adhering to specifications such as I.S.S., B.S.S., or ASTM as required by customers. Additionally, AECO utilizes a cutting-edge German Laser-Marking machine for precise part marking and identification. These advanced technologies and processes contribute to the company's commitment to delivering. We are ISO 9001:2015 certified and the largest Cylinder Liner Manufacturers in India, having a production capacity of 5000 liners per day.

America (USA) |

Australia |

Argentina |

Algeria |

Azerbaijan |

Bangladesh |

Belarus |

Bolivia |

Brazil |

Bulgaria |

Cameroon |

Canada |

Chile |

Colombia |

Czech Republic |

Djibouti |

Dominic Republic |

Ecuador |

Egypt |

Ethiopia |

Germany |

Ghana |

United Kingdom (UK) |

Greece |

Guatemala |

Indonesia |

Iran |

Iraq |

Israel |

Jordan |

Kazakhstan |

Kenya |

Lebanon |

Libya |

Malaysia |

Mauritania |

Mexico |

Mongolia |

Morocco |

Mozambique |

Myanmar |

Netherlands |

Nigeria |

Panama |

Peru |

Philippines |

Poland |

Qatar |

Romania |

Russia |

Saudi Arabia |

Singapore |

Slovenia |

Somalia |

South Korea |

South Africa |

Spain |

Sri Lanka |

Sudan |

Syria |

Taiwan |

Tanzania |

Thailand |

Tunisia |

United Arab Emirates (UAE) |

Uganda |

Uruguay |

Uzbekistan |

Venezuela |

Vietnam |

Yemen |

Zimbabwe |

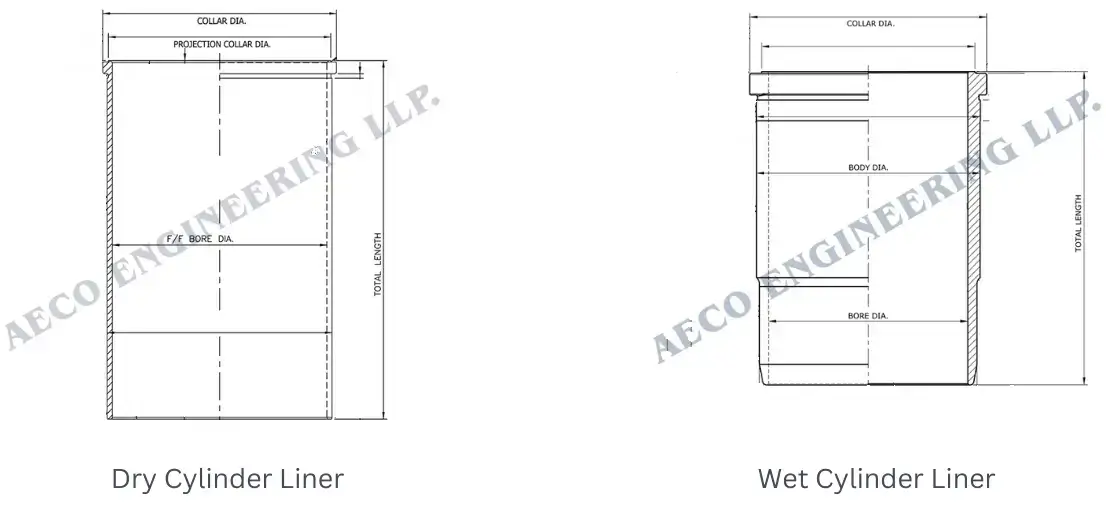

Minimum order quantity for Dry Cylinder Liners is 300 pieces and Wet cylinder liners is 500 pieces.

We can offer material compositions using Molybdenum, Nickel, Copper, Boron or as per customer specifications meeting to respective country standards.

We outsource from reliable and tested factories.

Yes, only to direct bulk Importers.

Yes, we manufacture liners using Centrifugal Casting Process.

Yes, we do.

Yes, We do private labeling of cylinder liners.

AECO Engineering is a leading cylinder liner manufacturer in India, known for our high-quality cylinder liners. We utilize centrifugal casting techniques and quality materials to ensure reliable performance for various automotive applications.